Alubond® A1

Product Description:

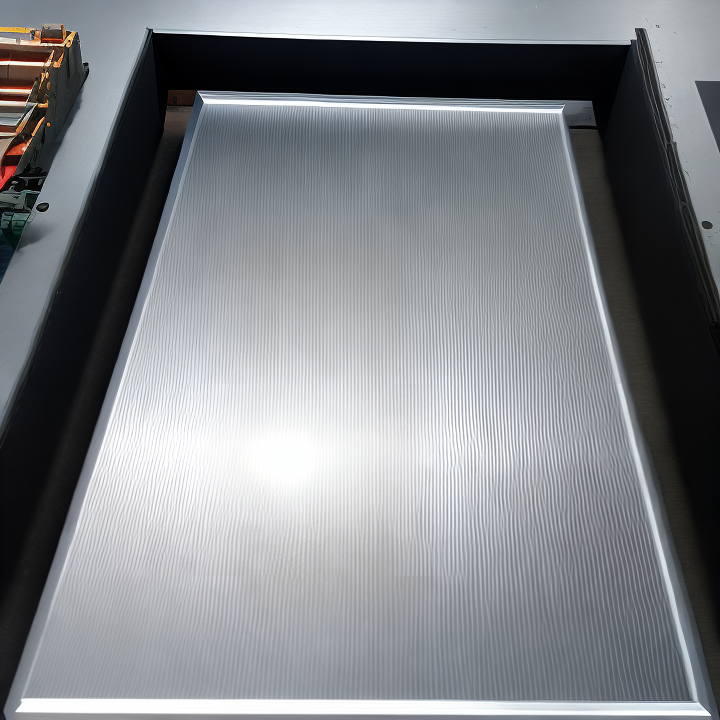

The Aluminum Composite Panel (ACP) is a high-quality, lightweight cladding material that offers superior functionality and aesthetics. It comprises two aluminum sheets bonded to a non-aluminum core, ensuring durability and resilience.

Benefits:

1. Lightweight: Despite its robustness, ACP is incredibly lightweight, making it easy to handle and install.

2. Versatility: It can be cut, bent, and shaped to fit various architectural designs.

3. Durability: ACP is resistant to weather, impact, and UV rays, ensuring longevity.

4. Aesthetics: Available in a range of colors and finishes, ACP enhances the visual appeal of any structure.

Features:

1. High rigidity and strength

2. Excellent thermal insulation

3. Sound and heat resistance

4. Easy maintenance and cleaning

Applications:

ACP is ideal for various applications, including:

1. Building exteriors: ACP is perfect for cladding systems, facades, and canopies.

2. Interiors: It can be used for partitions, false ceilings, and wall coverings.

3. Signage: ACP’s smooth surface makes it suitable for digital printing, signboards, and billboards.

FAQ:

1. Q: Is ACP weather-resistant?

A: Yes, ACP is designed to withstand harsh weather conditions, including heavy rain, sunlight, and wind.

2. Q: Can ACP be used for interior design?

A: Absolutely! ACP is versatile and can be used for various interior applications like wall coverings, partitions, and false ceilings.

3. Q: How do I clean ACP?

A: ACP is easy to maintain. It can be cleaned with a mild detergent and water.

4. Q: Is ACP fire-resistant?

A: While standard ACP has some fire resistance, specific fire-resistant ACP variants are available for higher safety requirements.

5. Q: Can ACP be recycled?

A: Yes, ACP is recyclable, making it an environmentally friendly choice for construction and design projects.

Types of aluminum composite panel

Aluminum Composite Panels (ACPs) are widely used in various industries due to their versatility and durability. Here are some common types:

1. PVDF Aluminum Composite Panel: This type is made up of polyvinicidene fluoride resin, which is chemically bonded to the aluminum surface. It is highly resistant to harsh weather conditions, making it ideal for outdoor applications.

2. PE Aluminum Composite Panel: This type uses polyethylene as the core material. It is lightweight and flexible, making it suitable for interior decoration and signage.

3. Fireproof Aluminum Composite Panel: This type is made with a fire-resistant plastic core to meet high safety standards. It is used in areas where fire safety is a concern, such as commercial buildings and public spaces.

4. Brushed Aluminum Composite Panel: This type has a unique brushed finish on the aluminum surface, giving it a distinct aesthetic appeal. It is often used in interior design and architectural applications.

5. Mirror Aluminum Composite Panel: This type has a mirror finish on the aluminum surface, providing a high-end look. It is commonly used in interior decoration, especially in areas requiring a sense of space.

6. Wood Finish Aluminum Composite Panel: This type mimics the appearance of wood while maintaining the advantages of ACPs. It is used in applications where a natural wood look is desired but the durability of aluminum is needed.

7. Nano Aluminum Composite Panel: This type is coated with nano-materials that provide self-cleaning properties. It is ideal for exterior wall cladding as it can maintain a clean appearance for a long time.

8. Chameleon Aluminum Composite Panel: This type changes color depending on the viewing angle, providing a dynamic and vibrant aesthetic. It is often used in high-end architectural and design applications.

Each type of ACP has its unique properties and applications, offering a wide range of options for different needs and requirements.

Pros and Cons of Using aluminum composite panel

Pros of Using Aluminum Composite Panel:

1. Durability: Aluminum composite panels are highly durable and can last for a long period of time.

2. Versatility: These panels are available in a wide range of colors and finishes, making them suitable for various design needs.

3. Lightweight: Despite their durability, these panels are lightweight, making them easy to handle and install.

4. Resistance: They are resistant to weather, heat, and corrosion, making them suitable for outdoor use.

5. Maintenance: They require minimal maintenance, as they do not stain or fade easily.

6. Cost-effective: Compared to other materials, aluminum composite panels are relatively inexpensive.

Cons of Using Aluminum Composite Panel:

1. Installation: The installation process of these panels can be complex and requires professional expertise.

2. Limited Flexibility: Although they are versatile in terms of design, these panels are not very flexible, which can limit their use in certain applications.

3. Noise: Aluminum composite panels can produce noise when subjected to high wind pressure.

4. Environmental Impact: The production process of these panels can have a negative impact on the environment, as it involves the extraction and processing of aluminum.

5. Fire Risk: While they are resistant to heat, these panels can contribute to the spread of fire, as they contain a layer of plastic sandwiched between two aluminum sheets.

aluminum composite panel Reference Specifications (varies for different product)

Aluminum Composite Panel (ACP) is a popular material used in various applications due to its excellent mechanical and physical properties. The reference specifications for ACP may vary depending on the product, but the following are some general specifications:

1. Panel Thickness: ACPs are typically available in thicknesses ranging from 2mm to 6mm. The choice of thickness depends on the intended application and structural requirements.

2. Aluminum Thickness: The aluminum layer in ACPs usually ranges from 0.12mm to 0.5mm. This thickness is crucial for the panel’s rigidity and impact resistance.

3. Panel Size: Standard panel dimensions are 1220mm x 2440mm, but other sizes can be customized according to project requirements.

4. Coating: ACPs are often coated with PVDF or PE. PVDF coatings are highly resistant to weather, acid, and alkali conditions, making them suitable for outdoor applications. PE coatings, on the other hand, are ideal for interior applications due to their excellent rigidity and smoothness.

5. Core Material: The core material of ACPs is typically a low-density polyethylene (LDPE) or a fire-resistant mineral core. The choice of core material affects the panel’s fire resistance and thermal insulation properties.

6. Color: ACPs are available in a wide range of colors and finishes, including metallic, solid, mirror, wood, and marble patterns. The color choice depends on the aesthetic requirements of the project.

7. Mechanical Properties: ACPs should have excellent mechanical properties, including high tensile strength, high flexural strength, and good impact resistance.

8. Fire Resistance: Depending on the application, ACPs may need to meet specific fire resistance standards.

9. Environmental Impact: ACPs should be recyclable and environmentally friendly.

These are general specifications and may vary depending on the manufacturer and the specific product. Always refer to the manufacturer’s product data sheets for accurate information.

Applications of aluminum composite panel and Type of Companies use aluminum composite panel

Aluminum Composite Panels (ACPs) are widely used in various industries due to their versatility, durability, and lightweight nature. They are primarily used in the construction industry for external cladding of buildings, insulation, and signage. ACPs are also used in the transportation industry for making lightweight vehicles, in the aviation industry for building aircraft structures, and in the marine industry for constructing ship hulls.

In the advertising industry, ACPs are used to make billboards, signboards, and digital printing due to their excellent flatness and rigidity. They are also used in interior design for creating partitions, false ceilings, and wall coverings. In the electronics industry, ACPs are used for making panels for electronics and electrical equipment.

Companies that use ACPs range from construction and architecture firms to transportation and aviation companies. Large construction companies like Bechtel, Fluor, and Vinci use ACPs for building and infrastructure projects. Automotive companies like Ford, General Motors, and Tesla use ACPs for manufacturing lightweight vehicles. Aviation companies like Boeing and Airbus use ACPs for constructing aircraft structures. Advertising companies like WPP, Omnicom, and Publicis use ACPs for making billboards and signage. Electronics companies like Samsung, Sony, and LG use ACPs for making panels for their products. Interior design firms also use ACPs for creating stylish and modern interiors.

Quality Testing Methods for aluminum composite panel and Work Process Use aluminum composite panel

Quality testing methods for aluminum composite panels (ACP) include visual inspection, peel strength testing, impact resistance testing, and thermal expansion testing.

Visual inspection involves checking the surface of the panel for any defects such as scratches, dents, or discoloration. Peel strength testing measures the bond strength between the aluminum sheet and the core material. This is done by applying a force to peel the aluminum sheet from the core and measuring the resistance. Impact resistance testing evaluates the panel’s ability to withstand impacts without deforming or breaking. This is done by dropping a weight onto the panel from a certain height and assessing the damage. Thermal expansion testing measures how much the panel expands or contracts when exposed to different temperatures. This is important for panels that will be used in environments with significant temperature changes.

The work process of using ACP involves several steps. First, the panels are cut to the desired size using a panel saw or CNC machine. The edges are then smoothed and cleaned to remove any dust or debris. Next, the panels are installed onto the building structure using a variety of methods such as riveting, screwing, or adhesive bonding. The panels are typically installed in a sequential manner, starting from the bottom and working up to the top. After installation, the panels are sealed to prevent water ingress and to improve thermal insulation. Finally, the panels are inspected for any defects or installation errors.

In conclusion, quality testing methods and the work process for using ACP are crucial to ensure the durability, safety, and aesthetic appeal of the finished product.

Comprehensive Analysis of aluminum composite panel Costs: Including Visible and Hidden Costs

Aluminum composite panels (ACP) are a popular choice for building cladding due to their durability, lightweight, and aesthetic appeal. However, understanding the full cost of ACPs requires considering both visible and hidden costs.

Visible costs include the initial purchase price of the panels, which can vary depending on the size, thickness, and finish of the panels. The average cost can range from $15 to $35 per square meter. Installation costs are another visible expense, which can vary based on the complexity of the project and the labor rates in your area.

Hidden costs, on the other hand, are often overlooked but can significantly impact the total cost of ownership. These include maintenance costs, which can be substantial if the panels are not properly cared for. For instance, cleaning and repairing damaged panels can add to the overall cost.

Another hidden cost is the potential for increased insurance premiums. Some insurers may charge higher premiums for buildings with ACP cladding due to perceived fire risks.

Lastly, the lifespan of the panels should be considered. While ACPs are durable, they will eventually need to be replaced. The cost of replacement, as well as the disposal of the old panels, should be factored into the total cost.

In conclusion, while aluminum composite panels may seem cost-effective upfront, it’s crucial to consider both visible and hidden costs to understand the true cost of ownership. These include initial purchase and installation costs, ongoing maintenance, potential insurance increases, and eventual replacement and disposal costs.

Payment Terms for aluminum composite panel and Bulk Purchase Discounts and Price Variances Among Suppliers

Payment terms for aluminum composite panels typically involve an initial deposit, often around 30% of the total cost, with the balance due upon delivery or within a specified period after the order is placed. Some suppliers may offer a discount for full payment upfront or for large orders.

Bulk purchase discounts are common in the industry. Suppliers may offer tiered pricing, where the per-unit price decreases as the quantity ordered increases. This is to incentivize larger orders and to account for the lower costs associated with mass production.

Price variances among suppliers can be due to a number of factors. These include the quality of the aluminum composite panels, the size of the order, the location of the supplier, and the current market price for aluminum. Suppliers located in regions with lower labor costs may be able to offer lower prices, while those that use higher quality materials or have more advanced manufacturing processes may charge more.

It’s also worth noting that the price of aluminum on the global market can fluctuate due to factors such as changes in supply and demand, economic conditions, and geopolitical events. This can affect the prices offered by suppliers.

In conclusion, when purchasing aluminum composite panels, it’s important to consider not just the upfront cost, but also the payment terms and potential discounts for bulk purchases. It’s also crucial to understand the factors that can cause price variances among suppliers, and to take these into account when comparing quotes.

Chinese Regulations and Industry Standards Certifications for aluminum composite panel

In China, the production and use of aluminum composite panels (ACPs) are regulated by several industry standards and certifications. The primary standard is GB/T 17748-2016, which specifies the requirements for classification, requirements, test methods, inspection rules, marking, packaging, transportation, and storage of ACPs. This standard is applicable to ACPs used for building curtain walls and interior decoration.

Another important standard is GB/T 22412-2008, which provides the limit of harmful substances in building decoration materials, including ACPs. This standard is crucial for ensuring the safety and health of the users.

In terms of fire safety, GB 8624-2012 is the classification standard for the combustion performance of building materials and products. ACPs must meet the requirements of this standard to ensure they do not contribute to the spread of fire.

Furthermore, ACPs must also comply with GB 50009-2012, the load code for the design of building structures, to ensure they can withstand the loads they will be subjected to in use.

In addition to these national standards, there are also industry certifications that ACP manufacturers can obtain to demonstrate the quality and safety of their products. For example, the China Quality Certification Centre (CQC) offers a voluntary product certification for ACPs. This certification involves a comprehensive evaluation of the product, including factory inspections and product testing, to ensure it meets the relevant standards.

In summary, the production and use of ACPs in China are regulated by a series of national standards covering various aspects such as product specifications, safety, and environmental impact. Manufacturers can also obtain industry certifications to further demonstrate their commitment to quality and safety.

Navigating Import Regulations and Customs for aluminum composite panel from China

Importing aluminum composite panels from China involves understanding and complying with various import regulations and customs procedures.

Firstly, you need to classify your product under the Harmonized System (HS) code. For aluminum composite panels, the HS code is 7606.12. This is crucial for determining import duties and taxes.

Secondly, ensure compliance with the standards set by the American Society for Testing and Materials (ASTM). The ASTM B209 standard, for instance, specifies the general requirements for flat-rolled aluminum-alloy products.

Thirdly, be aware of anti-dumping duties. The U.S. has imposed anti-dumping duties on aluminum composite panels from China, which can significantly increase the cost of your imports.

Fourthly, ensure your supplier has the necessary export licenses. Without these, your shipment may be held at customs, causing delays and additional costs.

Fifthly, prepare the necessary import documentation. This includes a Bill of Lading or Airway Bill, Commercial Invoice, Packing List, and Arrival Notice.

Lastly, consider hiring a customs broker. They can handle the complex customs clearance process, ensuring your goods are imported smoothly and legally.

Remember, failure to comply with import regulations can result in penalties, seizure of goods, and damage to your business reputation. Therefore, it’s crucial to understand and follow these rules when importing aluminum composite panels from China.

Procurement and Considerations when Purchasing aluminum composite panel

Procuring aluminum composite panels (ACP) requires careful consideration of several factors to ensure quality, durability, and value for money.

Firstly, consider the quality of the aluminum. High-quality aluminum is resistant to corrosion, ensuring longevity. Check the panel’s thickness, as it directly impacts durability and strength. A thickness of 3-4mm is generally recommended for ACPs.

Secondly, consider the core material. ACPs are made of two aluminum sheets with a core material sandwiched between them. The core can be made of polyethylene (PE) or mineral-filled fire-resistant (FR) material. FR cores are more fire-resistant than PE cores, so consider the fire safety regulations in your area.

Thirdly, consider the coating. PVDF (Polyvinylidene Fluoride) and PE (Polyethylene) are the most common coatings. PVDF is more durable and has better weather resistance, but it’s also more expensive.

Fourthly, consider the color and finish. ACPs come in various colors and finishes, including mirror, brushed, wood grain, and marble. Choose a color and finish that suits your project’s aesthetic requirements.

Fifthly, consider the supplier’s reputation. Look for suppliers with a track record of delivering high-quality products and good customer service. Ask for references or check online reviews.

Lastly, consider the cost. While it’s important to get a good deal, don’t compromise on quality for the sake of saving a few dollars. Remember, the cost of replacing poor-quality panels can be much higher than the initial cost of purchasing high-quality ones.

In conclusion, when procuring ACPs, consider the quality of the aluminum, the core material, the coating, the color and finish, the supplier’s reputation, and the cost.

Sourcing aluminum composite panel from China: Opportunities, Risks, and Key Players

Sourcing aluminum composite panels (ACPs) from China presents both opportunities and risks.

Opportunities include cost-effectiveness, as Chinese manufacturers often offer competitive prices due to low labor costs and high production capacity. China’s vast manufacturing industry also ensures a wide variety of ACPs in terms of colors, finishes, and sizes. Additionally, China has a well-established logistics network, facilitating efficient and timely delivery of goods.

However, risks are also present. Quality control can be a concern, as some Chinese manufacturers may compromise on quality to cut costs. Language barriers and cultural differences may also pose challenges in communication and negotiation. Furthermore, potential changes in trade policies and tariffs could impact costs and supply chain stability.

Key players in China’s ACP industry include Guangzhou Xinghe ACP Co Ltd, Shanghai Alubang Decorative Material Co Ltd, and Shandong Jiyu Building Materials Co Ltd. These companies have a strong reputation for quality and have extensive experience in exporting to international markets.

In conclusion, while sourcing ACPs from China can be cost-effective, it is crucial to conduct thorough due diligence on potential suppliers to mitigate risks. It is also beneficial to stay informed about changes in international trade policies that could affect the ACP industry.

Cultivating Successful Business Relationships with Chinese aluminum composite panel Suppliers

Building successful business relationships with Chinese aluminum composite panel suppliers requires understanding and respecting their business culture, communication style, and negotiation tactics.

Firstly, it’s crucial to understand the importance of Guanxi, or relationships, in Chinese business culture. Building trust and personal connections is often more important than contractual agreements. Regular face-to-face meetings, social outings, and gift-giving are common ways to strengthen Guanxi.

Communication style in China tends to be indirect and non-confrontational. It’s important to avoid causing ‘loss of face’ by criticizing or contradicting your Chinese counterparts in public. Instead, express concerns or disagreements privately and diplomatically. Patience and politeness are highly valued.

Negotiation is an art in China. Chinese suppliers often start with a high price, expecting you to bargain. Don’t be afraid to negotiate, but do so respectfully. Also, understand that decisions often take time, as they usually involve several layers of management.

Furthermore, it’s essential to understand the Chinese market and regulatory environment. This includes import/export regulations, quality standards, and local business practices. Having a local representative or partner can be very helpful in navigating these complexities.

Finally, remember that successful business relationships are built on mutual benefit. Show your Chinese suppliers how they can benefit from doing business with you, not just how you can benefit from them.

In conclusion, cultivating successful business relationships with Chinese aluminum composite panel suppliers requires patience, respect, and a deep understanding of Chinese business culture and practices. By building strong Guanxi, communicating effectively, negotiating respectfully, understanding the local market, and demonstrating mutual benefit, you can establish and maintain successful business relationships with Chinese suppliers.

Sustainability and Environmental Considerations in aluminum composite panel Manufacturing

Aluminum composite panel (ACP) manufacturing has significant environmental implications, necessitating the adoption of sustainable practices. The production process involves the extraction of aluminum, which can lead to deforestation, soil erosion, and biodiversity loss. Additionally, the energy-intensive smelting process releases greenhouse gases, contributing to climate change.

To mitigate these impacts, manufacturers are increasingly focusing on sustainability. One approach is using recycled aluminum, which reduces the need for raw material extraction and lowers energy consumption by up to 95%. Additionally, manufacturers can implement energy-efficient technologies and renewable energy sources in the production process to reduce carbon emissions.

Waste management is another critical aspect of sustainability in ACP manufacturing. Manufacturers can adopt a circular economy model, where waste from the production process is reused or recycled, minimizing landfill waste.

Furthermore, manufacturers can design panels for easy disassembly at the end of their life, facilitating recycling and reducing waste. The use of non-toxic adhesives and coatings can also minimize environmental harm and potential health risks.

In terms of environmental considerations, manufacturers should conduct regular environmental impact assessments to identify potential risks and implement mitigation strategies. Compliance with environmental regulations and standards, such as ISO 14001, can also ensure responsible manufacturing practices.

In conclusion, sustainability and environmental considerations are integral to ACP manufacturing. By adopting sustainable practices, manufacturers can reduce their environmental footprint, contribute to a circular economy, and ensure the long-term viability of their operations.

The Evolution and Market Trends in aluminum composite panel Industry

The aluminum composite panel (ACP) industry has seen significant evolution and market trends over the past few years. Initially, ACPs were primarily used in the aviation industry due to their lightweight and durable properties. However, with advancements in technology and manufacturing processes, they have found extensive applications in the construction and automotive industries.

One of the key market trends is the increasing demand for sustainable and energy-efficient materials. ACPs are recyclable and have excellent thermal insulation properties, making them an ideal choice for green buildings. This trend is expected to drive the growth of the ACP market in the coming years.

Another trend is the rising demand for fire-resistant ACPs, especially in high-rise buildings. This has led to the development of fire-retardant ACPs, which are expected to gain significant market share in the near future.

The ACP industry is also witnessing a shift towards digital printing. Digital printing technology allows for the creation of customized designs on ACPs, enhancing their aesthetic appeal. This trend is particularly prevalent in the signage and advertising industry.

Furthermore, the market is experiencing a surge in demand for ACPs in the automotive industry. The lightweight nature of ACPs contributes to fuel efficiency, making them a preferred choice for electric and hybrid vehicles.

In conclusion, the ACP industry is evolving rapidly, driven by technological advancements and changing market trends. The increasing demand for sustainable, fire-resistant, and aesthetically appealing materials is expected to shape the future of the ACP industry.

The Role of Agents and Sourcing Companies in Facilitating aluminum composite panel Purchases from China

Agents and sourcing companies play a crucial role in facilitating aluminum composite panel purchases from China. They act as intermediaries between the buyer and the manufacturer, ensuring a smooth and efficient transaction process.

Firstly, they help in identifying reliable manufacturers. China is a vast market with numerous manufacturers, making it challenging for foreign buyers to find a trustworthy supplier. Agents and sourcing companies have extensive knowledge and connections in the industry, enabling them to recommend reputable manufacturers.

Secondly, they assist in price negotiation. They understand the local market dynamics and pricing strategies, which can help buyers get the best deal. They also ensure that the agreed price includes all costs, such as shipping and customs duties, to avoid unexpected expenses.

Thirdly, they oversee quality control. They inspect the products before shipment to ensure they meet the buyer’s specifications and quality standards. If any issues are identified, they liaise with the manufacturer to rectify them promptly.

Lastly, they handle logistics and documentation. They coordinate with shipping companies to arrange transportation and ensure the products are delivered on time. They also manage the necessary paperwork for customs clearance, reducing the administrative burden on the buyer.

In conclusion, agents and sourcing companies provide invaluable support in facilitating aluminum composite panel purchases from China. They simplify the procurement process, mitigate risks, and save time and resources for the buyer.

How to use import and export data website importyeti.com to search the company and aluminum composite panel

1. Open your web browser and go to www.importyeti.com.

2. On the homepage, you will see a search bar at the top. Type in the name of the company you are interested in and click on the “Search” button.

3. The website will then display a list of all the import and export data related to that company. You can see the details of each shipment, including the product description, the country of origin, the consignee, the shipper, etc.

4. To specifically find data related to aluminum composite panels, use the “Filter” function. Click on the “Filter” button located at the top right corner of the data list.

5. A drop-down menu will appear. Click on “Product Description” and type in “aluminum composite panel”. Click on “Apply Filter”.

6. The website will then display only the data related to aluminum composite panels. You can further refine your search by adding more filters, such as the date range, the country of origin, etc.

7. To export the data, click on the “Export” button located at the top right corner of the data list. You can choose to export the data in CSV or Excel format.

8. A download link will be sent to your email. Click on the link to download the data.

Remember, ImportYeti is a powerful tool for researching international trade data. It can help you understand the import and export activities of a company, find potential suppliers or customers, and analyze market trends.

How to use Chinese Business Search Platform: qcc.com to check aluminum composite panel company credit

1. Open the website: Visit qcc.com, the Chinese business search platform.

2. Language: If you are not a Chinese speaker, use the translation feature of your browser to translate the page into English or your preferred language.

3. Search: In the search bar, type the name of the aluminum composite panel company you want to check and click on the search icon.

4. Company Profile: From the search results, click on the company’s name to open its profile. Here, you will find general information about the company such as its registration status, legal representative, registration capital, establishment date, and business scope.

5. Credit Information: Scroll down to the “Credit Information” section. Here, you can see the company’s credit score, any violations, and legal disputes.

6. Financial Data: Check the “Financial Data” section for the company’s revenue, net profit, taxes, total assets, and other financial indicators.

7. Intellectual Property: The “Intellectual Property” section shows the company’s patents, trademarks, copyrights, and software copyrights.

8. Business Relationships: The “Business Relationships” section displays the company’s shareholders, subsidiaries, and key personnel.

9. Risk Information: The “Risk Information” section provides details about any business risks associated with the company, such as legal proceedings, changes in equity, and negative news.

10. Verification: Verify the information you find with other sources to ensure its accuracy.

Remember, while qcc.com provides a wealth of information, it should not be the sole source for making business decisions. Always consult with a professional or conduct further research when necessary.

Overcoming Challenges and Facilitation of Sourcing aluminum composite panel from China

Sourcing aluminum composite panels (ACP) from China can be challenging due to language barriers, quality control issues, and logistical complexities. However, these challenges can be overcome with strategic planning and effective communication.

Firstly, partnering with a local sourcing agent who understands the Chinese market and language can bridge the communication gap. They can negotiate on your behalf, ensuring you get the best deal possible.

Secondly, quality control is crucial. It’s essential to request samples before placing a large order. You should also consider visiting the manufacturing site if possible. Alternatively, hiring a third-party inspection company can ensure the ACP meets your quality standards.

Lastly, managing logistics can be complex due to customs regulations and shipping costs. Working with a reputable freight forwarder can simplify this process. They can handle customs clearance and ensure your goods are delivered on time.

Furthermore, understanding China’s business culture is beneficial. Building a good relationship with your supplier can lead to better prices and priority service.

In conclusion, while sourcing ACP from China can be challenging, these obstacles can be overcome with careful planning, local partnerships, and a focus on quality control and logistics.

FAQs on Sourcing and Manufacturing aluminum composite panel in China

1. What is an aluminum composite panel?

An aluminum composite panel (ACP) is a type of flat panel that consists of two thin aluminum sheets bonded to a non-aluminum core. It’s widely used for architectural cladding or facades of buildings, insulation, and signage.

2. Why source and manufacture ACP in China?

China is one of the leading producers of ACP due to its advanced manufacturing technology, high-quality products, and competitive pricing. The country also has a vast supply chain network, making it easier to source raw materials.

3. How to find a reliable ACP manufacturer in China?

You can find reliable manufacturers through online platforms like Alibaba, Made-in-China, or attend trade shows. It’s crucial to verify the manufacturer’s certifications, product quality, production capacity, and reputation before making a decision.

4. What are the common certifications for ACP in China?

Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and CE marking for compliance with health, safety, and environmental protection standards in the European Economic Area.

5. What is the average lead time for ACP production in China?

The average lead time varies depending on the order quantity and manufacturer’s schedule. However, it typically ranges from 2 to 4 weeks.

6. What are the payment terms for ACP orders in China?

Payment terms are often negotiable. Common practices include a 30% deposit before production and the balance before shipment, or letter of credit at sight.

7. How are ACPs shipped from China?

ACPs are usually shipped in containers via sea freight. It’s important to consider factors like shipping cost, transit time, and local customs regulations when planning logistics.